- Mazgaon, Mumbai, Maharashtra

sales@shreddersandshredding.com

Shredder Machines

Leading Manufacturers, Exporters and Wholesaler of 7.5kw Plastic Bottle Shredder, Low Power Consumption, High Capacity: 500 kgs/Hr, Aluminium Shredder Machine, Aluminum UBC Scrap Bale Shredder Machine, Automatic Biomedical Waste Shredding Machine, Automatic Food Waste Shredder Machine, Biomass Shredding Machine, Cement company paper bag shredder machine, Chicken Waste Shredder Machine, Direct Industrial Wood Pallet Shredder Machine, Direct Industrial Wood Pallet Shredder, Capacity : 100 Pcs/Hr, Double Shaft Cattle Bone Shredder Machine, Double Shaft Coconut Husk Shredder Machine, Double Shaft Industrial Wood Shredder Machine, Double Shaft Municipal Solid Waste Shredder Machine, Double Shaft Raffia Bag Shredder Machine, Double Shaft Shredding Machine, Face Mask And Gloves Shredder Machine, Fish waste shredder machine, Gunny Bag Shredder Machine, Hard Drive Shredder Rental, Application/Usage: Industrial., Heavy Duty Waste Shredder Machine and Heavy Metal Scrap Shredder Machine from Mumbai.

| Business Type | Manufacturer |

| Brand Name | SHREDALL |

| Material | Hard Metal |

| Driven Type | Electric |

| Color | Gray |

| Condition | New |

| Power Type | AC |

| Power | 25kv |

| Automation Grade | Fully Automatic, Semi Automatic |

| Application | Industries |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Voltage | 440V |

| Capacity | 800-1000kg/h |

| Hardness | Metal |

| Type | Plastic Shredders |

| Weight | 900-1000kg |

| Warranty | 1yrs |

| Country of Origin | India |

| Product Code | SPL/G3-10 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

In today's world, where environmental sustainability is becoming increasingly important, efficient recycling solutions are crucial. Plastic waste, in particular, poses a significant challenge due to its non-biodegradable nature. However, with the advancement of technology, innovative solutions such as the 7.5kW Plastic Bottle Shredder have emerged, offering a promising way to tackle this problem head-on.

SHREDALL provides best solution for low power consumption at Best price with High quality performance.

The Working of Plastic Bottle Shredder

SHREDALL shredder is powered by a 7.5kW motor, providing impressive performance while consuming minimal power. This not only reduces operational costs but also aligns with sustainability goals by conserving energy. With our shredder, you can process up to 500 kilograms of plastic bottles per hour, making it a highly efficient solution for your recycling needs.

Key Features

Efficient: Handles 500 kg/hr, saving time and labor.

Low Power Consumption: Saves energy, reduces costs.

Versatile: Shreds PET, HDPE, etc., suitable for different industries.

Eco-Friendly: Minimal carbon footprint, promotes sustainability.

Shredding Material

It can efficiently shred various types of plastic bottles, including PET bottles, HDPE bottles, and more

Shredding Machine Type

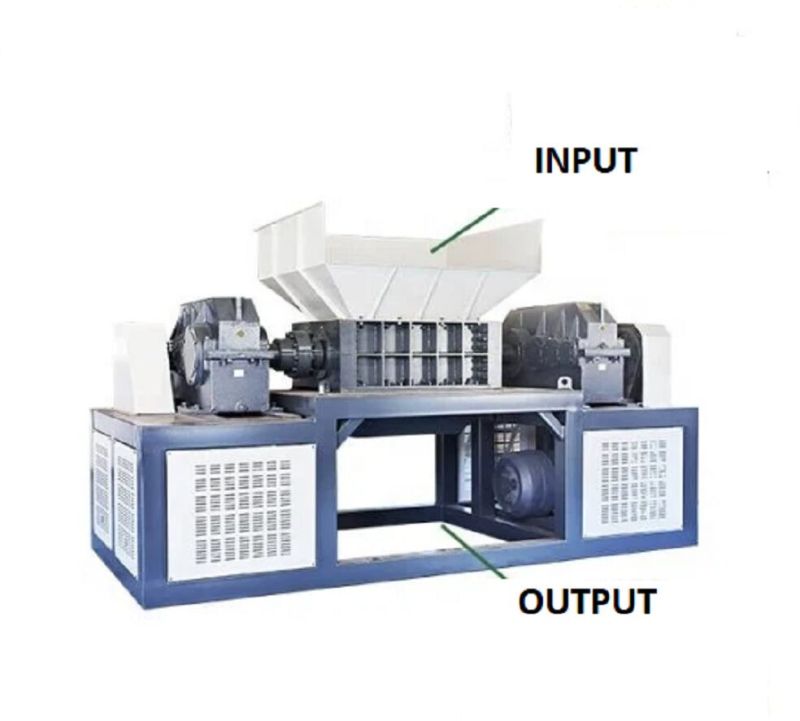

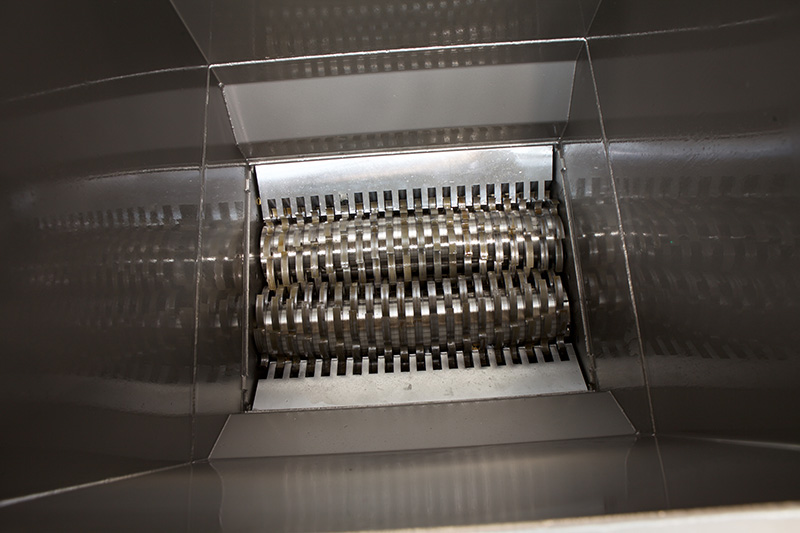

Double Shaft Shredding Machine: a powerhouse of shredding capability. With its dual-shaft design, it efficiently reduces material size, making it perfect for various industries.

Usage/Application

Our PET Bottle Shredder is versatile, finding applications in recycling plants, beverage production, plastic manufacturing, waste management, environmental cleanup, product destruction, and research.

Capacity

With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

SHREDALL Plastic Bottle Shredder combines high performance with easy installation, making it an ideal solution for various industries. With its powerful motor and robust design, it efficiently shreds PET bottles, maximizing productivity and reducing processing time.

Product Description

SHREDALL Plastic Bottle Shredder is a high-performance machine designed for efficiently shredding plastic bottles. It features a powerful dual-shaft design and high-torque motor, ensuring fast and effective shredding. With its compact and user-friendly design, it's easy to install and operate. Ideal for recycling plants and manufacturing facilities, this shredder maximizes productivity while reducing plastic waste volume.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Capacity | 500-5000kg/h |

| Power | 50KV |

| Material | Aluminium |

| Shredding Capacity | 500-5000 Kg |

| Automation Grade | Fully Automatic |

| Brand Name | Shredell |

| Country of Origin | India |

Non ferrous metal recycling shredders are designed by SHREDALL keeping in mind the type of scrap that will be shredder and the production quantity required, also of primary importance is the next process that the expensive metals will go through which determines the required output size.

As manufacturers of top-quality Aluminum Shredder Equipment for the recycling industry, We SHREDALL takes pride in our commitment to excellence backed with experience in the industry knowing what types of waste are shredded and how the machine should perform even after many years of use.

Our machinery is designed to meet the highest standards of performance and durability so that your investment pays back and you start to make profit from the venture from the second year itself, ensuring that our customers receive reliable and efficient equipment for their recycling needs.

With a global shipping network, we can deliver our Aluminum Shredder Equipment to customers all over the world. Whether you are looking for a single unit or a large-scale solution, we have the capacity to meet your requirements with prompt and secure delivery services.

Furthermore, at We SHREDALL, we stand behind the quality of our products with comprehensive warranties. This not only reflects our confidence in the durability of our equipment but also provides our customers with peace of mind knowing that they are investing in reliable and long-lasting solutions for their recycling operations.

The Basics of Aluminum Shredding

Our Aluminum Shredder Equipment is designed for recycling facilities. It handles large amounts of aluminum scrap quickly. Its sturdy build ensures durability.

At Shredall, we’re committed to providing cutting-edge solutions that empower recycling facilities to operate with efficiency and precision. Our Aluminum Shredder Equipment is a game-changer for the recycling enterprise.

Key Features

- High Capacity: The shredder handles large quantities of aluminum, improving productivity.

- Smart Sorting: It separates aluminum from other materials accurately, reducing waste.

- Easy to Use: The user-friendly interface simplifies operation.

- Safety First: Comprehensive safety features protect operators

Shredding Material

Aluminum shredders can shred different types of aluminum materials for recycling. This includes aluminum cans, foil, wire, scrap, extrusions, and profiles. These machines help turn old aluminum items into smaller pieces, making recycling easier and more efficient.

Usage/Application

Aluminum shredders are used in recycling plants, scrap yards, and manufacturing plants. They turn old aluminum items into smaller pieces for recycling. This helps reduce waste and production costs while promoting environmental sustainability.

Capacity

With shredder from 500 kgs/hr to 5000 kgs/hr , the machine is available for small , medium to large-scale operations.

Automation Grade

The Shredder Machine is automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

We SHREDALL, These machines are designed to efficiently shred aluminum materials while being simple to set up and operate. Their high-performance capabilities ensure fast and effective processing of aluminum scrap, while their user-friendly design makes them easy to install and use in various recycling facilities and manufacturing plants.

Contact Us

We are here to assist you. Feel free to contact us:

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Capacity | 500 Kg |

| Automatic Grade | Yes |

| Power | AC |

| Material | Mild Steel |

| Shredding Material | Aluminium UBC Scrap Bale |

| Shredding Capacity | 1-500 Kg/hr |

| Automation Grade | Automatic |

| Shredding Machine Type | Double Shaft |

| Brand Name | SHREDALL |

| Country of Origin | India |

| Warranty | 1 Year |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

We SHREDALL Is manufactured of Aluminum UBC (Used Beverage Can) Scrap Bale Shredder Machine is a piece of equipment used in recycling facilities to process aluminum cans that have been compacted into bales. These machines are designed to shred the bales into smaller pieces, making the aluminum easier to handle and process for recycling.

SHREDALL Aluminium UBC Scrap Bale Shredder Machine is a powerful and efficient solution for recycling industries worldwide. This machine is specifically designed to shred, crush, and recycle used beverage cans (UBC) and other aluminium scrap into a bale.

We are Manufacturer of Shredder Machine, You Get High Quality and Unbeatable Price All Over India and World Wide. By recycling aluminum, we reduce the need for mining, thus protecting our natural resources and reducing carbon emissions.

The Working of Aluminium UBC Scrap Bale Shredder Machine

The Aluminium UBC Scrap Bale Shredder Machine shreds whole bales of aluminium UBC scrap into small pieces. These pieces are then separated to remove any unwanted materials. The result is a pile of shredded aluminium, ready for further recycling processes. This machine is efficient, versatile, and contributes to environmental sustainability. Always follow the manufacturer’s instructions for safe operation.

Key Features

-

Robust Design: Built to withstand heavy-duty operations, ensuring long-term performance and durability.

-

High-Capacity Processing: Capable of handling large volumes of scrap, maximizing productivity.

-

Safety Measures: Equipped with safety features to protect operators and the machine itself.

Shredding Material

The shredding material in an Aluminium UBC Scrap Bale Shredder Machine is primarily used beverage cans (UBC) and other aluminium scrap.

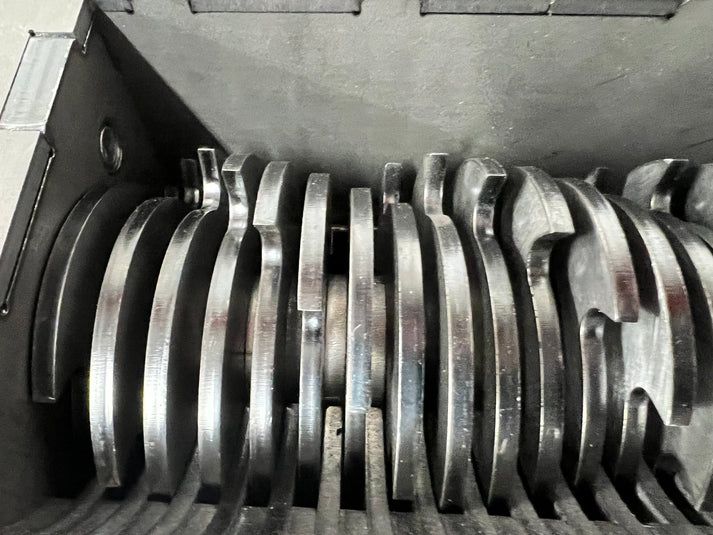

Shredding Machine TypeSHREDALL heavy-duty industrial primary Aluminium UBC Scrap shredders are double shaft shredders. These machines feature two rotating shafts with cutting blades that work together to efficiently shred Aluminium.

Usage/ApplicationThe SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine is primarily used in recycling industries for processing aluminium UBC scrap and other aluminium waste.

CapacityWith a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation GradeThe Shredder Machine is Automatic, which makes it easy to operate.

Motor PowerThe machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of OriginProudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy InstallationThe SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine excels in performance and is easy to install. It efficiently processes large volumes of aluminium scrap, separates aluminium accurately, and is designed with safety in mind. For installation, it features a user-friendly interface. Always follow the manufacturer’s instructions for safe operation.

Product DescriptionThe SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine is a high-performance recycling tool. It’s designed to process aluminium UBC scrap and other aluminium waste efficiently. The machine features a dual-shaft design for effective shredding, advanced sorting technology for precise material separation, and a user-friendly interface for easy operation. Safety features are integrated to ensure a safe working environment.

Contact UsWe are here to assist you. Feel free to Contact Us Call / WhatsApp / Email :

-

Email: info@shredall.in

-

+91 9820020754

Investing in an SHREDALL Aluminium UBC Scrap Bale Shredder Machine is a smart move for any recycling business. Its high-performance capabilities, safety features, and user-friendly interface make it a valuable asset. It not only enhances the efficiency of recycling aluminium scrap but also contributes to environmental sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Capacity | 300-400kg/h |

| Material | Hard Steel |

| Shredding Material | Waste |

| Automation Grade | Automatic |

| Brand Name | Shredell |

| Country of Origin | India |

| Warranty | 5years |

The biomedical waste stream is a significant concern for healthcare facilities worldwide. The safe and effective disposal of these wastes is vital to prevent the spread of infectious diseases and protect the environment. Today, we delve into an innovative solution for managing biomedical waste - Manufactured By SHREDALL high-capacity, automatic biomedical waste shredder.

Designing an automatic biomedical waste shredder with high production capacity involves several considerations, including safety, efficiency, and environmental impact.

Challenges in Biomedical Waste Management

Proper biomedical waste management poses significant challenges. These wastes are hazardous and could potentially spread diseases if not properly treated. Furthermore, the sheer volume of waste generated by healthcare facilities necessitates effective and efficient disposal methods.

The Solution: Automatic Biomedical Waste Shredder

SHREDALL Have Reliable Solution for Biomedical Waste, Our automatic Biomedical Waste Shredder offers a practical solution to these challenges. This state-of-the-art machine is designed to shred various types of biomedical waste, reducing their volume and making them safer for disposal.

How Does It Work?

The shredder operates by cutting the waste materials into smaller pieces, thereby reducing their volume. The shredded material is then easier to handle and can be processed further for safe disposal.

Key Features of the Biomedical Waste Shredder

The biomedical waste shredder boasts several features that make it a reliable and efficient solution for managing biomedical waste. These include:

-

High capacity: Able to handle large volumes of waste, making it suitable for use in large healthcare facilities.

-

Automatic operation: The machine operates automatically, reducing the need for manual handling of waste and minimizing the risk of contamination.

-

Robust construction: The shredder is built to withstand the rigors of continuous operation, ensuring a long service life.

-

Ease of maintenance: The machine is designed with easy maintenance in mind, reducing downtime and ensuring continuous operation.

Benefits of Using a Biomedical Waste Shredder

The use of a biomedical waste shredder offers several benefits:

-

Improved safety: By shredding the waste, the risk of infection from handling the waste is significantly reduced.

-

Reduced volume: Shredding reduces the volume of the waste, making it easier to handle and dispose of.

-

Efficient operation: The automatic operation of the shredder means less manual handling of waste, improving operational efficiency.

The Future of Biomedical Waste Management

As healthcare facilities continue to generate large volumes of waste, the need for effective waste management solutions will only grow. The automatic biomedical waste shredder represents a significant step forward in biomedical waste management, offering an efficient, safe, and reliable solution.

High Performance and Easy Installation

biomedical waste shredder not only ensures compliance with regulations but also contributes to a cleaner and safer environment. With its high production capacity, facilities can process large volumes of waste quickly and effectively, reducing the risk of contamination and infection.

Product Description

Incorporating an automatic biomedical waste shredder into your waste management system is not just a choice – it's a necessity for any healthcare facility looking to prioritize safety, efficiency, and environmental responsibility. We Provide World Wide Delivery and Best price.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SHREDALL |

| Automation Grade | Fully Automatic, Semi Automatic |

| Usage/Application | Food Waste |

| Voltage | 440V |

| Country of Origin | India |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Power Type | AC |

| Power | 25kv |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Capacity | 800-1000kg/h |

| Type | Industrial |

| Warranty | 1yrs |

| Product Code | SPL/G2-9 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

Our company, SHREDALL, takes pride in being a leading manufacturer of automatic food waste shredders. We are dedicated to providing high-quality products that are unmatched in the market. Our automatic food waste shredder is designed to meet the highest standards of performance and efficiency.

At SHREDALL, we understand the importance of quality and reliability when it comes to waste management solutions. That is why our automatic food waste shredder is built with precision engineering and cutting-edge technology to ensure optimal performance and durability.

The Working of Tire Shredder In India

-

Input: Users deposit food waste into a dishwasher-safe bucket.

-

Shredding: Waste passes through a high-strength shredder, breaking it down into smaller pieces.

-

Conversion: The machine automatically processes the waste, drying, grinding, and cooling it.

-

Composting: Within 24 hours, the machine produces a mulch-like substance ready for composting.

-

Output: The composted material can be used on plants or added to compost. Some models can also process bioplastics.

Key Features

-

Inbuilt Shredder: Reduces waste volume by 80-90% in the first step.

-

Fully Automatic: Controlled via a user-friendly touch screen controller.

-

No Discharge, No Emission: Produces no waste discharge or harmful gases.

-

Compact Size: Fits various spaces efficiently.

-

High-Quality Compost: Produces organic compost ready in 24 hours.

-

Noiseless, Odorless, Maintenance-Free: Operates quietly and requires minimal maintenance.

-

Cost-Effective: Reduces transportation costs to landfill sites.

-

In-House Waste Management: Minimizes reliance on external waste management.

-

Sturdy Design: Features a robust stand and body for durability.

-

Controlled Output: Ensures controlled particle output for easy handling.

-

Low Vibration: Base heavy design reduces vibrations and noise.

Shredding Material

SHREDALL automatic food waste shredder is indeed capable of processing a variety of food waste materials, including fruits, vegetables, meat and fish bones, dairy products, bread, grains, and other kitchen scraps. Additionally, certain models are designed to handle bioplastics, such as compostable packaging materials, further enhancing their versatility in waste management applications.

Shredding Machine Type

The automatic food waste shredder is categorized as an "organic waste shredder" or "food waste shredder." It's designed to efficiently process food waste, coming in various types like batch feed or continuous feed models. These shredders reduce waste volume for composting or disposal, playing a key role in sustainable waste management.

Usage/Application

The SHREDALL automatic food waste shredder is versatile in institutional, industrial, and municipal settings. It efficiently reduces food waste volume for composting or disposal, making it essential for sustainable waste management.

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation Product Description

SHREDALL food waste shredders and compost machines are available for efficient waste management. The GDF Series Food Waste Shredder by GEP features corrosion-resistant cutters for shredding wet waste effectively. The Organic Waste Compost Machine with Inbuilt Shredder offers a decentralized solution, operating quietly and odorlessly while reducing transportation costs.he Automatic Food Waste Composting Machine Manufactured By SHREDALL

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Shredell |

| Driven Type | Electric |

| Power Type | AC |

| Automation Grade | Fully Automatic |

| Application | Industrial Use |

| Certification | ISO9001:2008 |

| Feature | Fast Cutting, Stable Performance |

| Voltage | 440V |

| Capacity | 10,000-15,000kg/h |

| Type | Biomass Shredder |

| Warranty | 1yrs |

| Country of Origin | India,India |

| Material | Hard Metal |

When it comes to Waste Wood Shredders for biomass fuel production, SHREDALL is the name you can trust. Our high-quality shredders are designed to provide efficient shredding solutions, ensuring that you get the right size of the materials in continuous large amounts non stop.

With our expertise and dedication to quality, we offer top-of-the-line Waste Wood and mixed agri waste Shredders that are tailored for biomass fuel production.

Contact us today to explore our range of shredding solutions and experience. The difference with SHREDALL is that you will get proper information and guidance along with the right equipment to succeed in the project.

Working of our Wood Shredder

In the evolving world of energy, the words of the day are sustainability and renewable energy. One such renewable source of energy is biomass, specifically derived from organic waste such as plants, animals, and wood. The latter is where SHREDALL's wood shredder comes into play, a breakthrough in the industry that efficiently transforms waste wood into biomass fuel.

Key Features

The SHREDALL Double Shaft Wood Shredder Machine is not just any ordinary machine. It is made with complete technical knowledge that makes it perform 2x times better than other machines with the same cost.

Wood shredders are the backbone of biomass energy production, reducing bulky organic materials into manageable sizes for better processing. SHREDALL's wood shredder is designed to shred organic materials into smaller sizes, releasing the natural energy trapped within the wood and making it suitable for biomass energy production.

Shredding Material

Our Waste Wood Shredder efficiently processes a variety of materials suitable for biomass fuel production, including branches, pallets, lumber scraps, wooden furniture, wood chips, and sawdust.

Shredding Machine Type

SHREDALL's wood shredder is equipped with solid, sharp knives that easily cut through thick materials.

Usage/Application

SHREDALL Waste Wood Shredder is used in wood processing, furniture manufacturing, construction, recycling centers, biomass power plants, pellet production, and briquette manufacturing for efficient biomass fuel production from waste wood.

Capacity

With a shredder from 10,000 kgs/hr to 15,000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is Semi-automatic/automatic Both are Available, which makes it easy to operate.

Motor Power

The machine runs on a 3-phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, the SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

One of the key benefits of SHREDALL's wood shredders is their versatility. They can handle a variety of biomass materials and can be transported right to the materials that require shredding. This makes them a more efficient and versatile solution for biomass production.

Product Description

Biomass energy is a renewable source of energy that can be produced from organic waste. By using a wood shredder, we can make this process more efficient and sustainable. This not only reduces our reliance on fossil fuels but also helps to reduce waste and pollution.

Conclusion The Future of Biomass Energy Lies in Efficient Wood Shredding

The future of biomass energy lies in efficient wood shredding. By using a wood shredder like the ones provided by SHREDALL, we can reduce the size of organic materials for better processing and more efficient energy production.

| Business Type | Manufacturer |

| Brand Name | SHREDALL |

| Driven Type | Electric |

| Color | Gray |

| Condition | New |

| Power Type | AC |

| Power | 25kv |

| Automation Grade | Fully Automatic |

| Application | Industries |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Voltage | 440V |

| Capacity | 800-1000kg/h |

| Type | Shredders,Two Shaft |

| Warranty | 1yrs |

| Country of Origin | India |

| Product Code | SPL/G3-18 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

Paper bags have long been used in the cement industry for packaging cement products. However, these bags often end up as waste after use, contributing to environmental pollution. The paper bag shredder machine offers a solution by efficiently shredding used paper bags into manageable pieces, which can be reused or recycled.

Cement companies face a unique challenge when it comes to disposing of their paper bags - a challenge that SHREDALL is uniquely equipped to solve. As the leading manufacturer of cement company paper bag shredder machines, we offer an unbeatable solution that is proven to meet the needs of cement producers across India and around the world.

The Working of Paper Bag Shredder

The paper bag shredder machine is designed to efficiently shred used paper bags into small pieces. Here's how it typically operates:

Feeding: Used paper bags are fed into the shredder's hopper.

Shredding: The machine shreds the bags into small, uniform pieces using sharp blades.

Collection: Shredded paper bag pieces are collected in a container for further processing.

Key Features

Our state-of-the-art shredder machines are designed specifically for the rigors of the cement industry, with heavy-duty construction and powerful motors that can handle even the toughest paper bags. Fully tested for performance and reliability, our machines deliver consistent, high-quality shredding that reduces waste volume and simplifies disposal.

Shredding Material

A cement bag shredder machine is used to crush cement bags into smaller particles for recycling. It’s a robust machine capable of handling large quantities, ensuring efficient and consistent shredding

Shredding Machine Type

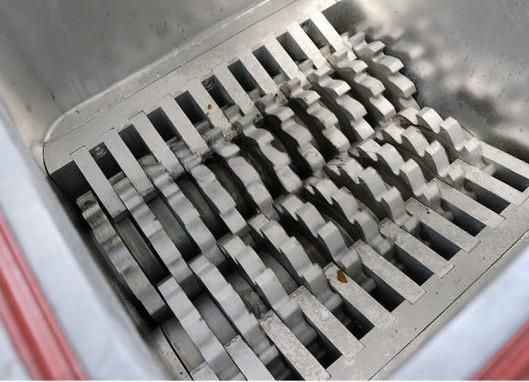

The shredding machine used by cement companies is typically a heavy-duty industrial dual shaft shredder specifically designed for paper bags, ensuring efficient and reliable shredding of the material.

Usage/Application

The dual shaft paper bag shredder machine is utilized in cement manufacturing plants to efficiently shred used paper bags, reducing waste volume and facilitating recycling or reuse of the shredded material in various applications within the cement industry.

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

High Performance and Easy Installation:

Our dual shaft paper bag shredder machine offers high performance, efficiently shredding used paper bags with ease. Its design allows for easy installation in cement manufacturing plants, ensuring quick setup and integration into existing processes.

Product Description

Our SHREDALL dual shaft paper bag shredder machine is an industrial-grade solution designed specifically for cement companies. With its robust construction and dual shaft design, it efficiently shreds used paper bags into small, uniform pieces, suitable for recycling or reuse in cement production. The machine's high-performance capabilities ensure quick processing of large volumes of paper bags

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SHREDALL |

| Country of Origin | India |

| Driven Type | Electric |

| Color | Gray |

| Condition | New |

| Power Type | AC |

| Automation Grade | Fully Automatic, Semi Automatic |

| Power | 25kv |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Capacity | 100-200kg/h |

| Type | Chicken Wash Shredder |

| Warranty | 1yrs |

| Product Code | SPL/G2-13 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

In today’s world, efficient waste management is a pressing concern. The SHREDALL Chicken Waste Shredder stands as a beacon of efficiency and sustainability in this domain. This high-performance equipment is designed to shred and process chicken waste, making it easier to handle and manage.

The SHREDALL Chicken Waste Shredder utilizes advanced technology to break down chicken waste into smaller pieces. This not only saves on storage space but also facilitates the composting process. The resulting shredded waste can be used as compost or converted into valuable resources such as biofuels or animal feed.

The Working of Chicken Waste Shredder In India

Feeding the Waste: Chicken waste is fed into the shredder, often via conveyor belts for automated feeding.

Shredding Process: Advanced technology breaks down the waste into smaller pieces, reducing volume and making it easier to handle.

Output: The shredded waste can be used as compost, biofuels, or animal feed. Some systems generate steam from the process for electricity production.

Benefits: Chicken waste shredders streamline waste management, reduce volume, and turn waste into valuable resources.

Key Features

Introducing the SHREDALL Chicken Waste Shredder:

🔹 Efficient Waste Reduction: Our shredder significantly reduces waste volume by efficiently shredding chicken waste.

🔹 Resource Recovery and Recycling: Designed for optimal material separation, it promotes recycling, contributing to a circular economy.

🔹 User-Friendly Operation: Easy-to-use controls and advanced safety features make integration into waste management processes smooth.

🔹 Robust Construction: Strong and durable, ensuring minimal downtime.

Revolutionize waste reduction and resource recovery with SHREDALL Chicken Waste Shredder. Say goodbye to waste challenges and embrace a sustainable future!

Shredding Material

The SHREDALL chicken waste shredder efficiently processes various materials, including chicken waste into smaller manageable pieces.

Shredding Machine Type

The SHREDALL chicken waste shredder is a dual-shaft industrial shredding machine, designed for efficient processing of chicken waste.

Usage/Application

The SHREDALL chicken waste shredder, a dual-shaft industrial shredding machine, is used for processing chicken waste in various applications such as agriculture, food processing, and waste management.

Capacity

With a shredder from 50kgs/hr to 100kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is Automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3-phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, the SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The SHREDALL Chicken Waste shredders are designed for easy installation and operation. They are equipped with user-friendly controls and safety features With Robust Performance, making them easy to operate

Product Description

The SHREDALL Chicken Waste Shredder is a state-of-the-art solution for managing chicken waste. This machine is designed with advanced technology to efficiently shred chicken waste into smaller pieces. The shredded waste can then be used for composting or converted into valuable resources such as biofuels or animal feed.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Material | Recycled Wood, Wood/Plastic Pallet,Hard Metal |

| Brand Name | SHREDALL |

| Country of Origin | India |

| Style | Double Faced |

| Feature | Durable, Eco Friendly, Fine Finishing, Heat Resistance, Loadable, Termite Proof |

| Type | Plastic Industrial Pallets, Wood Industrial,Industial |

| Warranty | 1 Year |

| Product Code | SPL/G2-8 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

In today's environmentally conscious world, efficient waste management is paramount. Industrial wood and plastic pallet shredders play a crucial role in this endeavor, offering a sustainable solution for processing pallets and reducing waste volume. In this guide, we'll explore the benefits, features, and applications of direct feeding industrial wood and plastic pallet shredders.

We SHREDALL are Top Manufacturer In India and Provide the Best Solution High Quality Shredder

The Working of Pallet Shredder In India

Wood and plastic pallet shredders cut pallets into small pieces using rotating blades. The shredded material can be repurposed for various applications, such as producing wood chips or mulch, or used as biomass fuel for energy production. These shredders help in waste management, save landfill space, and reduce disposal costs. They are cost-effective and improve overall productivity.

Key Features

SHREDALL Wood and plastic pallet shredders are robust machines that use rotating blades to shred pallets into small pieces. They can be fed manually or by a conveyor, and the output is small pieces of shredded material. These shredders are built with all steel materials and have a powerful motor for efficient operation. They also feature safety mechanisms like emergency stop buttons and interlock systems. The shredded material can be repurposed for various uses, contributing to waste management and recycling. These shredders are cost-effective, reduce the need for frequent waste collection, and improve overall productivity.

Shredding Material

To shred wood and plastic pallets effectively, you'll need a heavy-duty industrial shredder with a powerful motor and durable blades. Look for a shredder that can handle various sizes and types of pallets, with safety features, easy maintenance, and good customer support. Consider factors like throughput capacity, size, and environmental impact before making a purchase.

Shredding Machine Type

For shredding wood and plastic pallets, you'll want to use a heavy-duty industrial shredder. These machines are specifically designed to handle tough materials like wood and plastic with powerful motors and durable blades. Look for shredders designed for industrial or commercial use, rather than smaller, household models.

Usage/Application

Wood and plastic pallet shredders are mainly used in industrial settings like manufacturing plants and recycling facilities. They break down used or damaged pallets into smaller pieces for recycling or disposal, reducing waste volume and improving efficiency.

Capacity

With a shredder from 1000 kgs/hr to 5000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation Product Description

Introducing our Direct Feeding Industrial Wood and Plastic Pallet Shredder, a game-changer for waste management. Its dual-shaft shredding tech effortlessly handles wood and plastic pallets, maximizing recycling efforts. With a high-torque motor, durable construction, and safety features, it ensures efficient, reliable, and safe operation. Customizable options available. Upgrade your waste management process today!

Contact Us

| Business Type | Manufacturer |

| Brand Name | SHREDALL |

| Color | Grey |

| Certification | ISI Certified |

| Capacity | 300-400kg |

| Type | Plywood Pallets,Wood Pallet Shredder |

| Warranty | 1 Year |

| Country of Origin | India |

| Product Code | SPL/G3-17 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

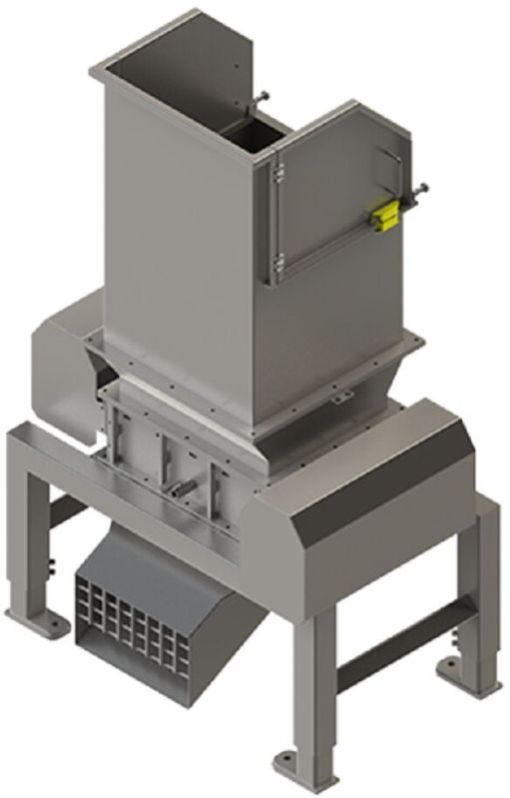

SHREDALL machine stands out for its efficiency and effectiveness - the Direct Industrial Wood Pallet Shredder. This powerful machine is designed to handle the toughest of tasks, transforming wood pallets into valuable resources.

Wood pallets are ubiquitous in the industrial sector, used for transporting goods of all kinds. However, once they’ve served their purpose, they often become a source of waste.

The Working of Wood Pallet Shredder

A Industrial Wood Pallet Shredder operates on the principle of shearing and crushing. The machine is equipped with sharp cutting blades that can cut through wood pallets. As the pallets are fed into the shredder, these blades cut and crush the wood into small chips.

Key Features

Efficiency: Capable of processing large volumes of wood pallets quickly.

Versatility: Adjustable settings for producing wood chips of various sizes.

Durability: Equipped with sharp, durable blades for effective shearing and crushing.

Shredding Material

The primary shredding material for a Wood Pallet Shredder is, as the name suggests, wood pallets. These are typically made from various types of wood, including hardwood and softwood species.

Shredding Machine Type

The single-shaft system ensures a high throughput rate, making it an excellent choice for industries that need to process large volumes of wood waste.

Usage/Application

The Industrial SHREDALL Wood Pallet Shredder finds its usage and application predominantly in the industrial sector. Industries that deal with large volumes of wood waste, such as manufacturing, logistics, and warehousing, can greatly benefit from this machine. It efficiently shreds used wood pallets into smaller pieces, which can then be recycled or repurposed. This could include creating mulch for landscaping, biofuel for energy production, or raw material for particleboard production.

Capacity

With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The SHREDALL IndustrialWood Pallet Shredder is a high-performance machine designed for industrial use. Shredder easy installation and robust design make it a valuable asset for industries dealing with wood waste.

Product Description

The SHREDALL IndustrialWood Pallet Shredder is an industrial-grade machine designed for the efficient and effective shredding of wood pallets. Its robust construction ensures durability, making it a valuable long-term investment for businesses dealing with wood waste. Let me know if you need more information

Contact Us

We are here to assist you. Feel free to contact us:

Email: info@shredall.in

+91 9820020754

Conclusion

SHREDALL Wood Pallet Shredder is a powerful and efficient solution for industries dealing with wood waste. Its ability to transform used wood pallets into smaller, reusable pieces makes it a key player in sustainable waste management. Easy to install and operate, this high-performance machine is a testament to SHREDALL’s commitment to quality and environmental sustainability. Investing in a SHREDALL Wood Pallet Shredder is not just a business decision, but a step towards a greener and more sustainable future.

| Business Type | Manufacturer |

| Material | Metal |

| Color | Grey, Creay |

| Condition | New |

| Application | Industrial |

| Certification | ISI Certified, ISO |

| Feature | Perfect Shape, High Strength, Fine Finished, Excellent Quality, Durable, Crack Proof, Corrosion Proof |

| Type | Double Shaft U Mixture Machine |

| Phase | Tripple Phase |

| Country of Origin | India |

| Brand Name | SHREDALL |

| Warranty | 1 Year |

| Product Code | SPL/G3-8 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

SHREDALL Double Shaft Cattle Bone Shredder Machine is an innovative and efficient piece of machinery designed to handle the unique challenges of shredding cattle bones. This machine is a must-have for businesses in the meat processing industry, offering a solution to the problem of waste management.

We are a manufacturer of many types of Shredder, We give Unbeatable Prices and Full Support All Over India and worldwide, You can easily contact us On WhatsApp, Call, and Email You Can Also Visit Our Factory Located In Mumbai.

The Working of Cattle Bone Shredder

A cattle bone shredder is a machine that breaks down bones into small pieces. It’s used in the meat industry to manage waste and create products like bone meal. The shredder has two shafts with cutting blades that crush the bones. The shredded bones can be used as fertilizer or animal feed. Some shredders use a microprocessor for energy-efficient operation. The exact mechanism can vary based on the shredder model and manufacturer. Always refer to the user manual for specific information.

Key Features

A SHREDALL cattle bone shredder crushes bones into small pieces. It has two stages of crushing with adjustable gaps. Some models have a bionic design for efficient crushing. The shredder can handle different types of bones and operate continuously. It’s energy-efficient and the output can be recycled

Shredding Material

The Double Shaft Cattle Bone Shredder Machine is a robust and efficient device designed for the shredding of cattle bones. This machine features a double-shaft design, which ensures a thorough and uniform shredding process.

Shredding Machine Type

The Double Shaft Cattle Bone Shredder Machine is a powerful and efficient device designed for the shredding of cattle bones. The machine is capable of handling a wide range of bone sizes and types

Usage/Application

The SHREDALL Double Shaft Cattle Bone Shredder Machine is primarily used in the meat processing industry for efficient waste management. It’s versatile, capable of shredding not just cattle bones, but also organic waste, paper, boards, and plastics

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

SHREDALL Double Shaft Cattle Bone Shredder is a high-performance device designed for making it a reliable choice for businesses in the meat processing industry Its robust design ensures long-term durability and high-capacity processing. The machine is also user-friendly, making installation and operation straightforward.

Product Description

The Double Shaft Cattle Bone Shredder Machine is a powerhouse of efficiency and versatility. Designed for high-capacity shredding, this machine is an indispensable tool in the meat processing industry. It’s equipped with two wear-resistant shredding tooth rollers, capable of shredding a wide range of materials

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Material | Metal |

| Shredding Material | Coconut Husk |

| Shredding Capacity | 500-1000 Kg/hr |

| Automation Grade | Automatic |

| Shredding Machine Type | Double Shaft |

| Brand Name | Shredell |

| Country of Origin | India |

| Warranty | 1 Years |

A green as well as brown coconut shells can be shredded in our double shaft shredder which is used to shred large quantities of coconuts fast on a daily basis, for SHREDALL quality and reliability are paramount.

We take pride in offering top-of-the-line double shaft coconut shredders that are built to last even in outdoor conditions. Our products are not only high-quality but also come with unbeatable prices and warranties, making them a smart investment for businesses worldwide.

With our commitment to excellence, we ensure that all our small, medium as well as large coconut shredders are manufactured to the highest standards, delivering efficient and reliable performance with every use. Whether you need in the farm or are in the food industry or agricultural sector, our agri shredders are designed to meet your specific needs and exceed your expectations.

When you choose SHREDALL for your coconut shredding needs, you can trust that you're getting a superior product that is built to last. Experience the difference with our world-class coconut shredders – shipped worldwide for your convenience.

The Basics of Double Shaft Coconut Shredder

The double shaft coconut shredder represents a significant advancement in shredding technology, specifically designed to address the unique characteristics of coconut husks. Unlike conventional shredders, which may struggle with the tough and fibrous nature of coconut husks, the double shaft design ensures thorough and efficient shredding.

Key Features

- Dual Shaft Configuration

- Robust Construction

- Versatility

- Efficient Drive System

- Safety Features

- Easy Maintenance

Shredding Material

The machine is designed to handle Coconut

Usage/Application The double shaft coconut shredder finds applications across various industries and sectors, including:

- Coconut processing plants: Efficiently processes coconut husks and other waste materials generated during coconut processing.

- Agricultural industries: Facilitates the conversion of coconut waste into valuable resources such as mulch, compost, or biofuel.

- Waste management facilities: Contributes to sustainable waste management practices by shredding coconut waste for recycling or disposal.

Capacity

With a shredder from 100 kgs/hr to 5000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is Automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3-phase power supply, ensuring efficient and reliable performance.

Country of Origin

Made in India, the SHREDALL industrial Shredder Machine are designed and manufactured entirely in INDIA.

Product Description

Coconuts are not only a popular tropical fruit but also a source of various byproducts, including coconut husks. However, managing coconut husk waste efficiently has long been a challenge due to its tough and fibrous nature. Traditional methods of disposal often lead to environmental pollution and resource wastage. In response to this problem, the introduction of the double shaft coconut shredder promises a revolutionary solution, offering efficient and sustainable coconut waste management.

Conclusion

The introduction of the double shaft coconut shredder marks a significant advancement in coconut waste management technology. With its efficient shredding capabilities, robust construction, and versatility, the shredder offers a sustainable solution for processing coconut husks and other coconut waste materials. By revolutionizing coconut waste management practices, the double shaft coconut shredder contributes to environmental conservation and resource optimization in coconut-producing regions worldwide.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SHREDALL |

| Driven Type | Electric |

| Color | Gray |

| Condition | New |

| Power Type | AC |

| Power | 25kv |

| Automation Grade | Fully Automatic |

| Application | Industries |

| Certification | ISO9001:2008, ISO |

| Feature | Durable, Heat Resistance,Hard Structer,Eco Friendly |

| Voltage | 440V |

| Capacity | 800-1000kg/h |

| Type | Wood Shredder, Wood Pallet Shredder |

| Warranty | 1yrs, 1 Year |

| After-Sales Service Provided | All India and Overseas |

| Country of Origin | India |

| Material | Hard Metal |

| Product Code | SPL/G2-16 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

in the world of industrial waste management, the shredall direct industrial wood pallet shredder machine with double shaft technology stands out as a powerful and efficient solution. designed to handle high volumes of wood waste, this machine is a game-changer for industries dealing with large quantities of pallets on a daily basis.

we are the top manufacturer in india, we provide high-quality shredder at unbeatable price all over india, contact and dial direct manufacturer shredall.

the working of direct industrial wood pallet shredder

the shredalldirect industrial wood pallet shredder machine with double shaft technology shreds wood pallets into smaller pieces. this process is by a robust motor that rotates two sets of cutting blades. the shredded wood is then ready for recycling or energy recovery.

key features

the shredall direct industrial wood pallet shredder machine with double shaft technology is a powerful and efficient solution for managing wood waste. its high capacity, versatility, and advanced technology make it an invaluable tool for industries dealing with large volumes of wood pallets. by improving waste management practices, this machine contributes to a more sustainable and efficient industrial environment, reinforcing shredall’s commitment to innovation and environmental responsibility.

shredding material

the shredall direct industrial wood pallet shredder machine shreds wood pallets into smaller pieces. this is crucial for efficient waste management and recycling, turning large wood waste into manageable pieces for further processing.

shredding machine type

the shredall direct industrial wood pallet shredder machine is a double shaft shredder. it’s designed for efficient shredding of wood pallets, making it a valuable tool in waste management and recycling industries.

usage/application

the shredall direct industrial wood pallet shredder machine is primarily used in industries dealing with large volumes of wood waste, such as manufacturing and shipping industries. it shreds wood pallets into smaller pieces, making them easier to manage and process. these shredded pieces can then be recycled or used for energy recovery, contributing to more sustainable and efficient waste management practices. this makes the shredder a valuable tool in promoting environmental sustainability and efficient resource utilization in industrial settings.

capacity

with a shredder from 1000 kgs/hr to 2000 kgs/hr, the machine is available for small, medium to large-scale operations.

automation grade

the shredder machine is fully automatic, which makes it easy to operate.

motor power

the machine runs on a 3 phase power supply, ensuring efficient and reliable performance.

country of origin

proudly made in india, shredall industrial shredder machine is a testament to the country's manufacturing prowess.

high performance and easy installation

the shredall direct industrial wood pallet shredder machine is known for its exceptional performance. it features a powerful motor that ensures smooth operation and high torque, is user-friendly and easy to setup and install.

product description

the shredall direct industrial wood pallet shredder machine is a high-performance, double shaft shredder designed for efficient waste management. it shreds wood pallets into smaller pieces, making them suitable for recycling or energy recovery. its robust design, powerful motor, and advanced safety features make it an ideal choice for industries dealing with large volumes of wood waste. this machine is a testament to shredall commitment to innovation and environmental sustainability.

contact us

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Shredell |

| Usage/Application | Industrial Use |

| Certification | ISO 9001:2008 |

| Voltage | 440V, 580V |

| Type | Solid Waste Management |

| Warranty | 1 Years |

| Warrent | 1year |

We SHREDALL Our Double Shaft MSW Shredder is specifically designed to tackle the challenges of processing municipal solid waste, including household waste, commercial waste, and industrial waste. With its dual-shaft design and robust construction, this shredder offers unparalleled performance and reliability in shredding a wide range of materials.

The Basics of Municipal Solid Waste Shredder

A Double Shaft Municipal Solid Waste (MSW) Shredder is a machine that breaks down different types of household and commercial waste into smaller pieces. It has two rotating shafts with sharp blades that tear the waste apart. This shredder helps reduce the volume of waste, making it easier to manage and recycle. It's used in places like recycling centers and waste management facilities to process various materials like plastic, paper, metal, and organic waste. Overall, it's a handy tool for making waste disposal more efficient and environmentally friendly.

Key Features

-

Dual-Shaft Design

-

Versatile Shredding Capabilities

-

Heavy-Duty Construction

-

User-Friendly Operation

-

Safety Features

Shredding Material

A Double Shaft Municipal Solid Waste (MSW) Shredder can shred many different types of waste, including plastic, paper, metal, organic waste like food scraps, textiles, rubber, and wood. It's like a big, powerful machine with sharp blades that tears up waste into small pieces, making it easier to handle and recycle. It's used in places like recycling centers to help manage and process all kinds of waste materials.

Shredding Machine Type

A Double Shaft Municipal Solid Waste (MSW) Shredder is a specific type of shredding machine used to break down various materials found in household and commercial waste. It's called "double shaft" because it has two rotating shafts with sharp blades that tear up the waste

Usage/Application

The Double Shaft Municipal Solid Waste (MSW) Shredder is used in waste management and recycling to break down different types of waste. It's commonly found in places like recycling centers, composting facilities, and landfill sites. This shredder helps reduce the volume of waste, recover valuable materials for recycling, and make waste disposal more efficient.

Capacity

With a shredder from 1000 kgs/hr to 10,000 kgs/hr , the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The Double Shaft Organic Waste Shredder Machine is designed to offer high performance consistently. It is also easy to install and requires minimal maintenance, making it a cost-effective choice for businesses.

Moreover, the installation is done at the customer's premises if required, adding more value to your purchase.

Product Description

-

Dual-shaft design for powerful shredding.

-

Versatile shredding for different waste types.

-

Sturdy construction ensures durability.

-

Easy installation for quick setup.

Experience hassle-free waste management with our Double Shaft MSW Shredder!

Conclusion

In conclusion, our Double Shaft Municipal Solid Waste (MSW) Shredder offers a reliable and efficient solution for waste management needs.

With its dual-shaft design and versatile shredding capabilities, it can handle various waste materials effectively. Its sturdy construction ensures durability, while easy installation makes it convenient to integrate into existing waste management systems.

Choose our SHREDALL Double Shaft MSW Shredder for hassle-free waste management and contribute to a cleaner environment.

| Business Type | Manufacturer |

| Brand Name | SHREDALL |

| Driven Type | Electric |

| Shredding Material | Raffia Bag |

| Color | Gray |

| Condition | New |

| Power Type | AC |

| Power | 25kv |

| Automation Grade | Fully Automatic |

| Application | Industries |

| Size | Big |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Voltage | 440V |

| Capacity | 800-1000kg/h |

| Shredder Type | Double Shaft |

| Type | Industrial Shredders |

| Weight | 900-1000kg |

| Warranty | 1yrs |

| After-Sales Service Provided | All India and Overseas |

| Country of Origin | India |

| Shredding Capacity | 500-5000 kg |

| Shredding Machine Type | Industrial |

| Product Code | SPL/G3-19 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

Are you a part of the plastic industry, facing the challenge of managing used raffia bags efficiently? Look no further! Our Double Shaft Raffia Bag Shredder Machine offers the perfect solution. In this article, we'll explore how this machine can revolutionize your waste management process while boosting your productivity.

The Working of Raffia Bag Shredder Machine

Feeding: Place the used raffia bags into the machine.

Shredding: The dual shafts shred the bags into small pieces, ensuring thorough destruction.

Collection: The shredded raffia bag pieces are collected for recycling or disposal.

Key Features

These dual shafts work together to efficiently shred the bags into small, uniform pieces. The shredded material is then discharged for recycling or disposal. With its user-friendly design and safety features, this machine offers businesses an efficient solution for managing raffia bag waste, contributing to environmental sustainability.

Shredding Material

The Raffia Bag Shredder Machine is designed to shred used raffia bags into small, manageable pieces. These bags are typically made from polypropylene (PP) or other plastic materials. The machine's sharp blades cut through the bags, reducing them into uniform pieces suitable for recycling or disposal.

Shredding Machine Type

The Raffia Bag Shredder Machine is a powerful dual shaft shredder specifically designed to handle raffia bags with efficiency and precision.

Usage/Application

The Raffia Bag Shredder Machine is used in various industries for shredding used raffia bags, including agriculture, packaging, and construction, offering an efficient solution for waste management and recycling.

Capacity

With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

SHREDALL Raffia Bag Shredder Machine boasts high performance, efficiently shredding raffia bags with ease, coupled with easy installation for seamless integration into any operational setup.

Product Description

SHREDALL Raffia Bag Shredder Machine is a powerful dual shaft shredder designed specifically for handling raffia bags with efficiency and precision. Equipped with sharp blades and advanced technology, it efficiently shreds used raffia bags into small, uniform pieces, suitable for recycling or disposal. our shredder machine offers an ideal solution for businesses looking to streamline their waste management processes while contributing to environmental sustainability.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Gray |

| Condition | New |

| Application | Industries |

| Certification | ISO9001:2008 |

| Feature | High Strength, Durable, Easy To Use,Excellent Performance,Fast Cutting,Low Mentainance,Rust Free,Stable Performance |

| Type | Shredders |

| Country of Origin | India |

| Material | HARD Metal |

| Product Code | SPL/G2-2 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

Managing industrial waste can be a massive challenge, particularly when dealing with diverse materials such as metal, wood, plastic, and scrap tires, among others. One solution that stands out is the

Industrial Scrap Double Shaft Shredding Machine.

This high-capacity machine, manufactured by renowned companies such as SHREDALL, is designed to manage and reduce volumes of different materials efficiently.

The Working of Tire Shredder In India

The shredder operates on a low-speed, high-torque mechanism. It hosts two counter-rotating shafts that are ideal for destruction and primary size-reduction applications. The slow operation speed results in lower heat and dust generation, making it environmentally friendly compared to high-speed, low-torque shredders.

The material is fed into the shredding machine's box, which carries the shredding blade. The blade shreds the material into small pieces through various actions like tearing, squeezing, and shearing. The shredded material is then discharged from the lower box.

Key Features

The Industrial Scrap Double Shaft Shredding Machine comes with several unique features that enhance its performance:

-

Low-Speed Operation: The machine operates at low speed, resulting in lower noise levels and less dust, making it an environmentally-friendly option.

-

Programmable Control: The shredder comes with a programmable control feature and multi-stage speed regulation, suitable for crushing and processing different materials.

-

Uniform Output: The machine produces uniform particles, ensuring consistency in waste management.

-

Robust Design: The shredders are robust and rugged machines with throughput up to 20 tons/hr.

-

Lower Power Requirements: The machines require less power, leading to higher reliability and lower operational costs.

Shredding Material

SHREDALL industrial scrap double shaft shredding machine is versatile, handling various materials like metal, plastic, wood, rubber, e-waste, textiles, and more. It's an efficient solution for diverse industrial scrap shredding needs.

Shredding Machine Type

SHREDALL's industrial scrap double shaft shredding machine belongs to the category of double shaft shredders.

Usage/Application

The SHREDALL industrial scrap double shaft shredding machine is widely used in industries for shredding various materials such as metal scrap, plastic waste, wood, rubber, e-waste, textiles, and more. It's an essential tool for efficient waste management and recycling applications.

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The Industrial Scrap Double Shaft Shredding Machine, also known as a dual-shaft shredder, is a heavy-duty machine engineered for a vast range of applications and industries. one-stop solution for various industrial waste management needs.

Product Description

The SHREDALL industrial scrap double shaft shredding machine is a versatile solution for efficiently shredding a wide range of materials including metal scrap, plastic waste, wood, rubber, e-waste, textiles, and more. It's an essential tool for industries seeking efficient waste management and recycling solutions.

Contact Us

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Capacity | 800-1000kg/h |

| Power | 25KV |

| Material | Mild Steel |

| Automation Grade | Semi Automatic |

| Brand Name | Shredell |

| Country of Origin | India |

SHREDALL™ Face Mask and Rubber Gloves Shredder Machine is specifically designed to destroy contaminated PPE, the machine is simple double shaft shredder that completely destroys the equipment and solves the unique challenges posed by PPE waste as well as othOur er apparels and shoes etc. too.

Whether you're a pharma company, healthcare facility, high security government facility or a manufacturing plant, our shredder can efficiently process used face masks and rubber gloves, reducing them to manageable pieces for safe disposal. Features of Face Mask and Rubber Gloves Shredder

We understand that simplicity is essential when it comes to waste management equipment. That's why our Face Mask and Rubber Gloves Shredder Machine is designed for ease of use.

With user-friendly controls and tough cutters, it's easy to operate, even for laymen in the scrap yard.

Plus, its compact design and silent operation ensures it won't take up much space in your facility, making it suitable for businesses of all sizes.

Shredding Material

Our Face Mask and Rubber Gloves Shredder Machine is tailored for efficient processing of PPE waste. Designed to handle various materials like face masks, rubber gloves, and other PPE items, it ensures thorough shredding for responsible waste management. With its versatile capability and user-friendly design, our shredder offers a reliable solution for businesses seeking to streamline their PPE waste disposal processes.

Shredding Machine Type

Our Face Mask and Rubber Gloves Shredder Machine is available in double-shaft configurations of various capacities and sizes, offering versatility to meet your specific shredding needs.

Usage/Application

Our Face Mask and Rubber Gloves Shredder Machine is utilized across various industries and sectors for efficient PPE waste management. It's commonly used in healthcare facilities, retail stores, manufacturing plants, public spaces, educational institutions, office buildings, and waste management facilities to safely dispose of used face masks and rubber gloves, promoting cleanliness and hygiene.

Capacity

With shredder from 100 kgs/hr to 1000 kgs/hr , the machine is available for small , medium to large-scale operations.

Automation Grade

The Shredder Machine is Available in both automatic/semi-automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

Our Face Mask and Rubber Gloves Shredder Machine boasts high performance coupled with easy installation, making it an ideal choice for efficient PPE waste management. With its powerful motor and robust design, it effectively shreds PPE materials like face masks and rubber gloves. Additionally, its user-friendly installation process ensures quick setup, allowing businesses to streamline their waste management operations with ease and efficiency.

Product Description

Introducing our Face Mask and Rubber Gloves Shredder Machine: the ultimate solution for efficient PPE waste management. With high-performance capabilities and easy installation, this shredder effortlessly processes used face masks and rubber gloves, ensuring responsible disposal and promoting cleanliness and hygiene.

Conclusion

In conclusion, our Face Mask and Rubber Gloves Shredder Machine offers a streamlined solution for managing PPE waste effectively. With its high-performance capabilities and user-friendly design, it ensures efficient shredding of used face masks and rubber gloves, promoting cleanliness and hygiene across various industries and sectors. Invest in our shredder today for responsible PPE waste management and a safer, cleaner environment.

| Business Type | Manufacturer |

| Packaging Type | Wooden Box |

| Shredding Machine Type | Dual Shaft |

| Automation Grade | Automatic |

| Shredding Capacity | 500-1000 Kg/hr |

| Brand Name | SHREDALL |

| Country of Origin | INDIA |

| Type | Industrial Shredder |

| Color | gray |

| Material | Hard metal |

| Warranty | 1 year |

| Product Code | SPL/G3-4 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

SHREDALL Fish waste shredder machines are an innovative solution for managing and recycling fish waste. These machines play a crucial role in the seafood industry, helping to process and treat fish waste in an efficient and eco-friendly manner.

These SHREDALL shredders have significantly contributed to the production of fish emulsion fertilizer and other novel products, enhancing both their quality and quantity. They are adept at handling even the toughest fish, effortlessly shredding and breaking them down

The Working of Fish Waste Shredder

A Shredall fish waste shredder machine works by feeding fish waste into the shredder, where it’s shredded into small pieces by rotating blades. The shredded waste is then expelled for easy handling and disposal. The machine is cleaned after use to maintain its performance.

Key Features

Shredall fish waste shredder machine is designed for efficient shredding of fish waste into small pieces. It has a durable design for heavy-duty operations and is easy to clean and maintain. The machine is versatile and contributes to environmental sustainability by facilitating fish waste recycling.

Shredding Material

A fish waste shredder machine is a specialized device designed to efficiently process fish waste. But it also shreds other material like other Food Waste.

Shredding Machine Type

The Shredder Machine is a double-shaft which means it can shred Fish waste into small, manageable pieces for further processing.

Usage/Application

A Fish Waste Shredder is an efficient and eco-friendly solution for disposing of fish waste. This powerful machine transforms fish scraps into smaller, manageable pieces, enhancing efficiency and streamlining waste disposal processes. It’s ideal for ships and fish processing plants, reducing fish waste into small particles for easy handling and disposal. By shredding fish waste, you can create organic fertilizer or animal feed, promoting sustainability and reducing landfill waste. Invest in a Fish Waste Shredder for a safe, efficient, and environmentally conscious solution to fish waste disposal

Capacity

With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The SHREDALL Fish Waste Shredder is a high-performance, easy-to-install solution for efficient and eco-friendly fish waste disposal. Ideal for ships and fish processing plants, this robust machine from SHREDALL transforms large volumes of fish waste into smaller pieces for easy handling and disposal. Its compact design allows for flexible placement, and it can be easily integrated into existing waste management systems.

Product Description

Experience efficient and eco-friendly fish waste disposal with the SHREDALL Fish Waste Shredder. This high-performance, easy-to-install machine is perfect for ships and fish processing plants. It transforms large volumes of fish waste into manageable pieces, promoting sustainability and reducing landfill waste. Choose SHREDALL for a cleaner and more sustainable environment.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SHREDALL |

| Driven Type | Electric |

| Condition | New |

| Power Type | AC |

| Automation Grade | Fully Automatic, Semi Automatic |

| Application | Industries |

| Certification | ISO9001:2008 |

| Feature | Durable, Easy To Use, Excellent Performance, Fast Cutting, High Strength, Low Mentainance, Rust Free, Stable Performance |

| Voltage | 440V |

| Capacity | 800-1000kg/h |

| Type | Shredders |

| Warranty | 1yrs |

| Country of Origin | India |

| Product Code | SPL/G2-17 |

| Port | MUMBAI |

| Payment Terms | T/T |

| Delivery Time | 30 Days |

| Packaging Details | Wooden Box |

Gunny bags, also known as jute bags or burlap bags, have been a staple in the storage and transportation of goods for centuries. A Gunny Bag Shredder is a specialized machine designed to efficiently and effectively shred used gunny bags into small pieces. These pieces can then be recycled or repurposed, contributing to a more sustainable and eco-friendly world. We SHREDALL are Manufacturer of Gunny Bag Shredder, We Ship All Over INDIA and World Wide with support and unbeatable Price. Contact Us Today All Shredding Solution At One Placed.

The Working of Gunny Bag Shredder In India

-

Feeding: Gunny bags are fed into the shredding chamber.

-

Shredding: Sharp blades tear the bags into small pieces.

-

Collection: The shredded material is collected for disposal or further processing.

-